Future Interests

The electrochemical conversion of light alkanes, CO₂, and fine chemicals into higher-value products has gained increasing attention for its potential to enable sustainable and efficient chemical production. Unlike conventional chemical processes that require high temperature/pressure/corrosive reagents, electrochemical transformations use electricity to drive reactions. However, despite significant recent progress, the large-scale industrial implementation of these electrochemical processes remains elusive, underscoring the need for further research and development.

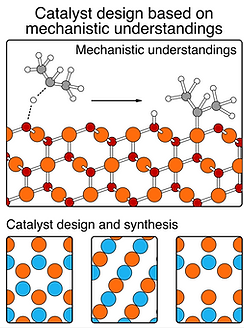

The real-world applications of electrocatalytic systems are hindered by the lack of high-performing electrocatalysts and mechanistic understandings of the target reactions. The overall vision of my future research direction is to develop efficient electrocatalytic systems for the sustainable chemical production and energy conversion by combining in-depth mechanistic investigations of surface-mediated reactions, and rational design and characterization of catalysts.

Electrochemical Light Alkane Activation

Light alkanes, such as methane, ethane, and propane, are abundant feedstocks from shale gas for chemical synthesis, but their direct conversion into high-value fuels and commodity chemicals remains a significant challenge. Conventional methods like cracking and dehydrogenation typically require high temperatures (200–600 °C) and/or pressures (5–50 bar). By contrast, electrochemical activation of light alkanes offers a more sustainable alternative capable of operating at lower temperatures and ambient pressure, as the activity of reactive species can be tuned by applied potentials. This short-to-mid-term research thrust focuses on gaining fundamental insights into reaction mechanisms and developing effective strategies of activating light alkaeans and convert them into oxygenates and olefins electrochemically.

CO₂ Further Upgrade

Producing liquid fuels and feedstocks from CO₂ with renewable energy is crucial for a sustainable economy. This process eliminates reliance on fossil fuels as the primary source for these products. Significant progress in CO₂ electroreduction (CO₂ER) has led to combined partial current densities for C₂ products, i.e., ethylene, acetate, and ethanol, exceeding 1 A/cm² with selectivities above 85%, while the production of C₃ products is still limited. Extending these C₂ products into compounds with longer carbon chains (C₃ to C₈) is crucial for a sustainable economy, providing provides a pathway for producing liquid fuels and chemical feedstocks solely from CO₂, but remains a major challenge. This mid-term research thrust aims to develop strategies for electrochemically converting C₂ products from CO₂ER into longer-chain alkanes, alkenes and oxygenates, and gaining fundamental mechanistic insights to guide catalyst design.

Electrochemical Cofactors

Enzymes are highly efficient catalysts for fine chemical transformations, including alkylation, hydroxylation, and redox reactions, due to their exceptional specificity and efficiency. However, these processes typically require stoichiometric cofactors to supply essential groups—such as alkyl, hydroxyl, and hydride—for substrate conversion. This long-term research thrust aims to develop general electrochemical methods for supplementing cofactors in enzymatic transformations, eliminating the need for stoichiometric addition of synthesized cofactors and expanding the substrate/product scopes.